Even with a compression ratio rule, you can have your "15 minutes of fame" if you like, but eventually you're going down because we can detect your indiscretion. You cheat by installing a bigger cam and although you go faster, we can catch you and "you're outta there". Likewise with a "cam lift" or "engine" vacuum rule. Very simply, with a carburetor rule, he who installs a "bigger" one usually goes faster, can be detected and penalized. Wrong! Not when it comes to compression "effect" rules! Do they exist so that we can go faster or slower to make racing more or less competitive? And, are those who break such rules punished or rewarded? Well you say, the obvious answers to these questions are "slower", "more competitive" & "punished". On the other hand, if it's a "compression effect" rule or the measurement of cranking compression in the cylinder as read on a compression gauge, then you have just pushed one of my buttons! However, before I begin my tirade, let us review why we have such rules as these in the first place. I for one, certainly have no quarrel with compression Ratio rules, because if you are talking true compression ratio, and it's properly measured and enforced, it is absolute. Cam "Lift" rules, engine "Vacuum" rules, "Carburation" rules and of course "Compression" rules. In order to hold costs down in oval track racing today we have numerous "RULE" classes. (This is the tech tip to check out if you have to deal with Vacuum rules at your local track!)Ĭompression Rules: "The Joker in the Deck"

2006 Stainless Valves: Do you really need them?.2005 Rod Lengths/Ratios: Much ado about almost nothing!.2004 Intake Restriction & over scavenging: "Waste not, Want not!".2003 Longer Exhaust Duration: Is this really necessary?.2002 What really causes intake reversion? Once and for all let us have the Truth!.2001 Compression Rules: "The Joker in the Deck".Unlike some others in the racing industry, I will make no assumptions, nor will I postulate any theory unless I have clearly labeled it as such. And just so there is no misunderstanding, I will limit the subject matter to those issues with which I have significant personal knowledge and experience. We'll be discussing subjects you won't read about in the magazines, but are nevertheless in great need of clarification for the racing community at large.

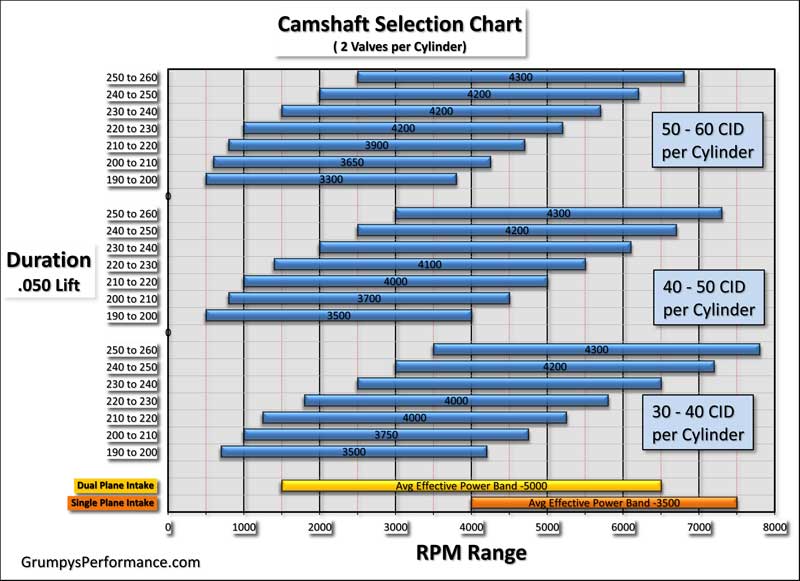

This first installment (in no particular order of magnitude) will contain the most common misconceptions in High Performance engine building today. General rule of thumb for acceptable dynamic compression ratio to run safely on pump gas is 8:1 maximum for engines with cast iron cylinder heads and 8.5:1 with aluminum cylinder heads.Book One of Tech Tips 2000TM features The Modern Myths of High PerformanceTM. However, that same 11:1 static compression ratio engine with the radical 259/269 duration camshaft would have a dynamic compression ratio in the neighborhood of 7.5:1, totally acceptable to run on pump gas. Therefore with the mild cam it will have a high dynamic compression ratio, probably 9.5:1+ which would be way too high to run safely on 91 octane gas. If you put a very mild camshaft (194/204 duration this cam will have an "early" IVC (intake valve closing point), and will "bleed off" less compression than a radical camshaft with 259/269 duration and a considerably "later" IVC. To give an example, lets say you're considering only pump gas for your engine, and it has a static compression ratio of 11:1. Unlike Static Compression Ratio, Dynamic Compression Ratio takes into account camshaft timing by considering the intake valve closing point in relation to the piston position.

#Camshaft compression calculator full#

Static Compression Ratio numbers are the ones you hear thrown around the most ("10:1 compression"), and it takes into consideration the full sweep volume of the cylinder in regard to its range of crankshaft stroke. This calculator will calculate both Static and Dynamic compression ratioĬompression Ratio is the ratio of an engine's cylinder volume vs.

0 kommentar(er)

0 kommentar(er)